Wraps

- Portable Fire Equipment

- Portable Fire Extinguishers

- Mobile Fire Extinguishers

- Fire Extinguisher Vehicle Brackets

- Fire Extinguisher Cabinets & Covers

- Fire Extinguisher Servicing Tools & Consumables

- Fire Blankets

- Fire Hose Reels

- Fire Hydrant Landing Valves & Equipment

- Hoses, Nozzles & Adapters

- Lay Flat Hoses

- Hose Reel Tails

- Hose Nozzles

- Branch Pipes

- Storz Forged Aluminium Adapters

- Storz Cast Aluminium Adapters

- Storz Cast Aluminium Hydrant Couplings

- NSW/MFB Hydrant Couplings & Adapters

- CFA Hydrant Couplings

- QLD Hydrant Couplings

- BIC Hydrant Adapters & Couplings

- Washers

- Lay Flat Tools & Service

- Lay Flat Hose Cabinets

- Anti-Tamper Device

- Extinguisher Spare Parts

- Portable Extinguisher Parts

- Mobile Extinguisher Parts

- ABE 30 & 50kg Parts

- ABE 70 & 90kg Parts

- Purple K 30 & 50kg Parts

- Purple K 70 & 90kg Parts

- BE 30 & 50kg Parts

- BE 70 & 90kg Parts

- AFFF 30L & 50L Parts

- AFFF 70 & 90L Parts

- Alcohol Resistant 30L & 50L Parts

- Alcohol Resistant 70L & 90L Parts

- Fluorine Free 30 & 50L Parts

- Fluorine Free 70 & 90L Parts

- CO2 22kg Parts

- CO2 45kg Parts

- Wall Brackets

- Extinguisher Gauges

- Pull Pins

- Valve Stems & Valves

- Valve Seats & Washers

- Neck O' Rings

- Dip Tubes

- Springs

- Hoses

- Handles

- Portable Extinguisher CO2 Parts

- Nozzles, Valves & Adapters

- Rivets

- Mobile Extinguisher CO2 Parts

- Recharge Equipment

- Sirens

- Knapsacks

- Anti-Tamper Device

- AS1851 Testing Equipment

- Solo 365 Test Kit & Accessories

- Solo Kits

- Testifire Kits

- Smoke & Heat Heads

- TruTest Smoke Detector Sensitivity Kits

- Smoke Cans & Capsules

- Smoke Bombs & Smoke Pens

- Poles

- Battery Charger & Batons

- Removal Tools

- Accessories

- Universal Flame Detector Testers

- Scorpion Remote Detector Testers

- Digital Multimeters

- Speaker Testing Equipment

- Battery Function Testers

- Cyclone Canless Air Systems

- Digital Light Meters

- Ultrasonic Liquid Level Test Kits

- Extinguisher Service Tools

- Measuring Scales

- Fire Detection Systems

- Addressable Fire Alarm Systems

- Vigilant MX1 Addressable Panels

- MX1 Addressable Fire Panels

- AS1668 Controls and Gas Controls for MX1

- Addressable Detection & 850EMTK Programmer

- Addressable Modules and Field Devices

- Graphic Monitoring Software - XLG Client Server

- Vigilant Empty Cabinets & Battery Boxes

- IP Interface Networking

- MX Hazardous Detectors / Devices

- Documentation and Manuals

- FlameStop Addressable Fire Alarm Systems

- EST3X Addressable Fire Alarm Systems

- Vigilant MX4428 & F4000 Addressable Systems

- Simplex 4100ESi Fire Panels

- Vigilant MX1 Addressable Panels

- Emergency Warning Systems

- QE20 EWCIE and QE90 EWIS

- Occupant Warning Systems

- Evacuation Speakers

- AS ISO 7240.24 Flush Mount Speakers

- AS ISO 7240.24 Low Profile Flush Mount Speakers

- AS ISO 7240.24 Surface Mount Speakers

- AS ISO 7240.24 Horn Speakers

- AS ISO 7240.24 Sound Projectors

- Horn Speakers

- Ceiling Ball Speakers

- Pendant Ball Speakers

- Speaker Accessories & Cages

- Vandal Resistant Speakers

- Speaker Grills

- Megaphone

- Speaker Testing Equipment

- Visual Alarm Devices

- WIP Phones & WIP Cabinets

- Manual Call Points & Accessories

- VOX Speech Intelligibility Test Kits

- VESDA ASD Detectors

- Conventional Fire Alarm Systems

- Batteries

- Cable

- Smoke, Heat, Co Alarms & Accessories

- AS1851 Testing Equipment

- Ancillaries

- Power Supplies

- Miscellaneous Tools & Items

- Gas Panel Accessories

- Flame Detection

- Baseline Data & Termination Cabinets

- Stat-X Aerosol Fire Suppression

- OSID Emitters & Imagers

- Conveyor System Detection

- Anti-Tamper Device

- Addressable Fire Alarm Systems

- VESDA & FAAST FLEX ASD

- VESDA & FAAST FLEX Detectors

- VESDA Life Expectancy 2015

- Xtralis AS1851.2012 Maintenance

- VESDA LCD Programmer & High Level Interfaces

- VESDA-E Backward Compatibility Table – Firmware Versions

- Filters & Spare Parts

- VESDA Software

- Pipe and Fittings

- Automatic Air Purging System

- 19" Rackmount Configurations

- Gas Detection for VESDA

- VESDA Remote Displays

- Power Supplies

- VSM4 Configuration & Monitoring Software

- VESDA Documentation & Manuals

- VESDA Life Expectancy 2015

- Xtralis AS1851.2012 Maintenance

- VESDA-E Backward Compatibility Table – Firmware Versions

- VESDA Product Manuals & Data Sheets

- VESDA Technical Tips

- VESDA Maintenance & Troubleshooting

- VESDA Design & Commissioning

- VESDA Industry Documents

- VESDA Aspirated Smoke Detection for Impulse (Jet) Fans in Carparks

- VESDA Refrigerated Cold Storage Facilities - Design Guide & Information

- VESDA Case Studies

- VESDA Movies

- Smoke Bombs & Smoke Pens

- FAAST FLEX Documentation & Manuals

- Water & Mechanical

- Fire Sprinklers

- Valves

- Butterfly Valves cw Monitor Grooved

- Brass Butterfly Valves cw Monitor BSP

- Outside Screw and Yoke Gate Valve Grooved

- Outside Screw and Yoke Gate Valve Flanged

- Pump Connectors

- Swing Check Valves Grooved

- Alarm Valves - Grooved

- Waste and Test Valves

- Water Motor Alarm Gongs

- Retard Chambers

- Mini Ball Valves Gauge Cocks

- Lockable Ball Valves

- Brass Swing Check Valves

- Brass Spring Check Valves - Brass Spindle

- Brass Y Strainers

- Brass Gate Valves Threaded

- Pressure Relief Valves

- Sprinkler Control Valve Assembly’

- Wafer Check Valves

- Lugged Butterfly Valve c/w Lever Handle + Gear Operator

- Double Check Valves

- Globe Throttling Valves Grooved

- Pressure Reducing Valves

- Bermad FP450 60 Tank Infill Valves

- Float Valves

- Solenoid Valves

- Brass Fittings

- Roll Groove

- Rigid Angle Pad Couplings

- Flexible Couplings

- Fast Connect Couplings

- Reducing Couplings

- Transition Coupling

- Standard Radius 90 Degree Elbows

- Short Radius 90 Degree Elbows

- Standard Radius 45 Degree Elbows

- Standard Radius 22.5 Degree Elbows

- Standard Radius 11.25 Degree Elbows

- Standard Radius Tees

- Short Radius Tees

- Reducing Tees

- Concentric Reducers GxG

- Concentric Reducers GxT

- End Caps

- End Caps with Eccentric BSP

- Mechanical Tees Grooved

- Mechanical Tees BSP Thread

- Grooved x Flanged Adaptors

- Grooved Hinged x Flange Adaptors

- Bull Head Tees Grooved

- Hydrant Elbows Grooved

- Grooved x BSP Adaptors

- HYDRANT LANDING VALVES

- FIRE HOSE REELS

- HOSES, NOZZLES & ADAPTORS

- Flexible Droppers

- Steel Pipe

- Gal Mal

- 90 Degree Elbows

- Tees

- 90 Degree Elbows MF

- Hex Nipples

- Sockets

- Square Plugs

- Unions Brass Seat

- Reducing Bushes

- 90 Degree Reducing Elbows

- Reducing Tees

- Reducing Hex Nipples

- Reducing Sockets

- Bull Nose Tees

- Service Tees

- Sprinkler MF Adaptors

- Table D Flange x BSP Thread

- 45 Degree Elbows

- 45 Degree Elbows MF

- End Caps

- Crosses

- Hangers

- 1 Piece Channel Clips

- 2 Piece Channel Clips

- Pear Bands

- Pear Bands HDG

- Nut Clips M10

- Nut Clips M12

- Mounting Plates

- Angle Brackets

- Beam Clamps

- Shallow Saddles

- Deep Saddles

- Twist Clips

- Wrap Around Pipe Clamps

- Purlin Clips

- Threaded Rod ZP

- Threaded Rod HDG

- Rod Joiners ZP

- Rod Joiners HDG

- Rod Cutters

- Channel and Angle

- Cantilever Brackets

- Medium Duty Saddles UN15

- Medium Duty Double Bolted Clamps UN16

- Medium Duty Yoke Clamps UN18

- Pipe Stand Clamps cw 50Nb Half Socket

- U Bolts

- 2 Piece Stainless Steel 316 Stand Off Bracket

- Mechanical Fasteners

- Monitor Switches

- Gal Steel

- Stainless Steel

- Consumables

- Valve Gaskets

- Flange Full Face Gaskets Table E

- Ring Gaskets

- Fibre Full Face Gaskets Table E

- Angus

- Bermad

- Chisolm

- Globe

- Grinnell Wormald

- Mather and Platt

- Matthew Hall

- Padde

- Reliable

- Shurjoint

- Star Model F Quell Guardian

- Tyco Central F

- Tyco Gem

- Tyco DV5

- Victaulic

- Viking

- Walter and CIE

- Waste and Test Kits

- Dorot Diaphragm

- Cometal Diaphragm

- Dobbie Dico Dual Booster

- Hydrant Landing Valves

- Pressure Gauges

- Traffolyte Signs and Stickers

- Tools

- Hydrant

- Hydrant Landing Valve Roll Groove

- Hydrant Landing Valve BSP

- Dual Hydrant Booster Roll Groove

- Dual Hydrant Booster BSP

- Single Point Booster Roll Groove

- Hydrant Booster Cabinets

- Booster H Patterns

- Dual Hydrant Risers

- Tank Suction Adaptor

- Dual Hydrant Booster Roll Groove High Pressure

- Quad Hydrant Booster Roll Groove

- Quad Hydrant Booster Roll Groove High Pressure

- Jacking Pumps and Accessories

- PPE

- Passive Fire

- Anti-Tamper Device

- Exit & Emergency Lighting

- Suppression Systems

- Fire Fighting Foam

- Passive Fire Equipment

- HYDRANT LANDING VALVES

- Cabinets

- Hardware & Fasteners

- Signage & Stickers

- Custom Engraved Sign

- Custom Printed Sign

- Custom Vinyl Cut Sign

- Signs and Labels

- Extinguisher Location Signs

- Fire Blanket Location Signs

- Extinguisher Charts/Cards

- Identification Signs

- Hose Reel Location Signs

- Fire Exit Signs

- Fire Door Signs

- Misc Signs

- First Aid Signs

- WIP Signs

- Offences Signs

- Alarm Signs

- Hydrant Signs

- Sprinkler Signs

- Fire Signs

- Pressure Test Stickers

- Extinguisher Pictographs

- Extinguisher Labels

- Water & Mechanical

- Pipe Markers

- Engraved Signs

- Hydrant Signs

- Hose Reel Signs

- Fire Hose Reel & Fire Signs

- Hydrant Pump & Valve Signs

- Sprinkler System Signs

- Fire Alarm Panel Signs

- Gas System Signs

- EWIS Panel Signs

- Electrical Signs

- Hazardous Signs

- Custom Block Plans

- Customised Signs

- Fire Safety Door Signs

- Cabinet Signs

- Commonly Used Signs

- CO Fire Detectors Installed Engraved Signs

- Signs for VADs and VWDs

- Vinyl Cut Lettering

- Block Plans & Evac Plans

- Snap Frames

- Cabinet Stickers

Latest News

Protecting Cold Storage Facilities using VESDA ASD – FlameStop TV Episode 50

Protecting Cold Storage Facilities using VESDA ASD – FlameStop TV Episode 50

FlameStop Wins Johnson Controls 2024 APAC Open Globe Award for Outstanding Sales Excellence

FlameStop Wins Johnson Controls 2024 APAC Open Globe Award for Outstanding Sales Excellence

New Quick-Connect Metal Grille Flush Mount Speaker - FlameStop TV Episode 49

New Quick-Connect Metal Grille Flush Mount Speaker - FlameStop TV Episode 49

Universal Flame Simulator Test Kit - FlameStop TV Episode 48

Universal Flame Simulator Test Kit - FlameStop TV Episode 48

Fire Rated Pipe Wrap - 150mm

BPW2150

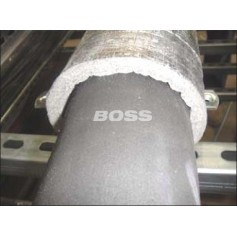

As a cost-effective alternative to pipe collars, we provide an intumescent Pipe Wrap to provide a high-expansion pressure seal penetrations of various plastics and polymers.

Ranging up to 150mm pipe diameter, Pipe wraps are suitable for a wide variety of pipe sizes.materials.

Standard pipe wrap offers 3 hour fire rating.

Availability date:

As a cost-effective alternative to pipe collars, we provide an intumescent Pipe Wrap to provide a high-expansion pressure seal penetrations of various plastics and polymers.

Ranging up to 150mm pipe diameter, Pipe wraps are suitable for a wide variety of pipe sizes.materials.

Standard pipe wrap offers 3 hour fire rating.

Downloads

TECHNICAL DATA SHEETS

CATALOGUE

SAFETY DATA SHEETS

Technical Details

- Approvals : EN1366.3 and AS1530.4(2005)

- Box Quantity : 20

- Fire Rating : 2 Hour

- Material : Polythene sleeve with graphite based intumescent

- Single Units : Yes

- Size (Thread/OD) : 150mm

Product Information

- Fire rates electrical and plumbing PVC pipes and conduits

- Easy to install and cost effective

- Use in floors and walls, including plasterboard

- Easy retrofit design

- Approved to EN1366.3 and AS1530.4(2005)

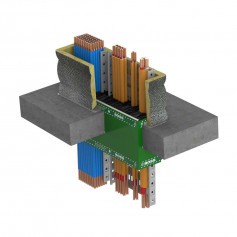

Pipe Wraps are intumescent composition - based elastomeric thermoplastic polymers, designed to provide high volume expansion and pressure sealing around PVC pipes and insulated metal pipes. Tested systems includes PVC, Polypropylene, MDPE, HDPE, HPPE and ABS up to a size of 200 mm diameter pipes through concrete / blockwork floors and walls as well as light weight partitions.

Benefits & Features

- Suitable for wall and floor installation

- The product is based on a thermoplastic composite and is therefore non - toxic

- Halogen free, contains no asbestos, ceramic, mineral fibres and is environmentally friendly

- Not affected by fungus, vermin or rodents

- Remains flexible between - 40 0 C to +130 0 C, long life and is easy to use

- Pipe Wraps are approved to multiple International Standards

- Test approvals up to 4hrs, with the highest FRL achieved is - /240/240, most applications FRL - /180/180 or /120/120

How Does it Work

FR Pipe Wraps are flexible intumescent seals for fire protection of fire walls and floors penetrated by plastic pipes and insulated plastic or metal pipes. When a fire occurs the intumescent material swells, crushing the plastic pipe or insulation and filling the gap with fire resistant material.

In lightweight wall construction, plasterboard or hollow wall construction, a steel pipe band must be used with the pipe wrap.

Performance

As the FR Pipe Wrap activates only in a fire it does not affect the performance or operation of the pipe in normal times. It is a simple to install, low maintenance solution for pipe penetrations seals in fire rated walls and floors. Note – like all fire stopping measures, installed FR Pipe Wraps must be properly maintained in accordance with the relevant Inspection & Testing Standard.

Installation

- Select wrap of relevant size to the pipe and place wrap around the pipe, with the ends overlapping each others.

- Remove plastic backing from adhesive strip and secure with adhesive tape supplied.

- Adjust the position of the wrap so that the edge is central within the wall or floor surface.

- When installing into masonry floors, ensure the wrap in flush with the underside of the slab.

- Fill annular gap with FireMastic - 300 or FireMortar - 360 to a depth of 5mm.

- Pipe wrap and the pipe can be sealed with FireMastic - 300.

- Maintain record of installation on the relevant as - built drawings or base building firestop schedule.

.jpg)

.jpg)